Energy optimisation in the process industry creates many opportunities

The process industry is a key part of Sweden’s economy and environmental strategy. It includes the production of raw materials such as steel, paper, pulp, batteries, and minerals. These products are essential for many other sectors and contribute to sustainable development. However, the process industry is also a major consumer of energy and a significant source of emissions. According to the Swedish Energy Agency, the process industry accounts for nearly 40 percent of Sweden’s total energy consumption and 25 percent of total greenhouse gas emissions.

Waste heat

Waste heat is generated as a by-product of various industrial processes and can be utilised in different ways to reduce energy losses and increase efficiency. One method is to recover the heat internally and use it for other purposes, such as space heating, drying, or evaporation. This reduces the need for external energy and lowers energy costs. Another approach is to export the heat to a nearby district heating network, where it can be used to heat homes, offices, or other buildings. This helps reduce greenhouse gas emissions and can generate new revenue streams for the industry.

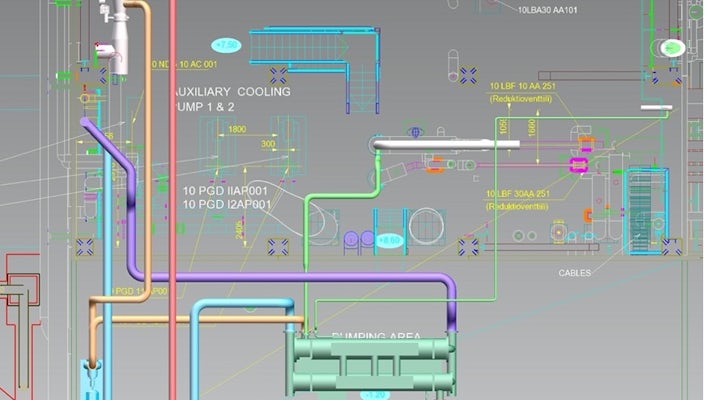

Cooling systems

One example of a system that can improve cooling efficiency in the process industry is centralised cooling. This involves using a shared chiller system to cool multiple processes, rather than having separate cooling systems for each process. This allows for heat exchange between processes and reduces the total cooling capacity required. In addition, a centralised cooling system is easier to maintain and control, as there are fewer components and a lower risk of leaks.

Lifetime extension

To extend the lifetime of an energy system within the process industry, it is important to identify and replace weak or worn components. This can be achieved through regular inspections and maintenance planning, where system performance, condition, and risks are analysed. By doing so, unplanned downtime can be avoided, faults prevented, and system functionality optimised. This results in cost savings and improved safety.

Energy optimisation in the process industry is beneficial not only for the environment but also for the economy. By saving energy and resources, the process industry can reduce costs, increase productivity and quality, and strengthen its market position. Energy optimisation in the process industry is therefore a key factor in creating a future that is sustainable, innovative, and competitive.